Powering truss innovation through digital transformation.

Powering truss innovation through digital transformation

The truss manufacturing industry which used to be long reliant on manual processes, is now experiencing a rapid shift towards digital transformation. To thrive in this new landscape, it's crucial to embrace innovation and choose the right software partner to develop and incorporate digital solutions into your operations.

That's where Q4US comes in. We're a trusted software development company with a laser focus on quality, serving clients across the US and Europe. Since 2018, our team has been at the forefront of building software tailored to the truss industry. This experience forms the core of our expertise, and we continuously refine our knowledge through ongoing projects.

We can be your trusted partner in navigating the digital transformation of the truss industry.

Our expertise empowers you to

Hit the ground running

Eliminate lengthy training periods and start seeing results immediately with our in-depth knowledge of truss manufacturing.

Boost

efficiency

Optimize your workflow and increase output with our tailored software solutions designed specifically for truss production.

Tap into real-world experience

Benefit from our team's hands-on expertise supporting truss production lines, ensuring solutions that align with your needs.

Invest

in the future

Stay ahead of industry changes with our adaptable solutions, built to grow alongside your business.

Elevate quality standards

Achieve consistently excellent results in your truss production with our quality-focused solutions.

Case Studies

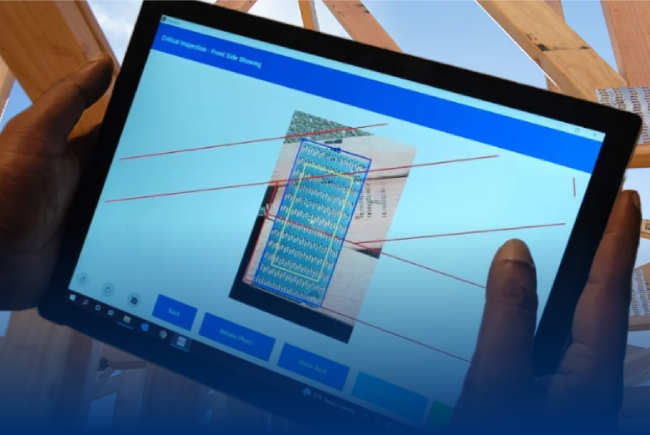

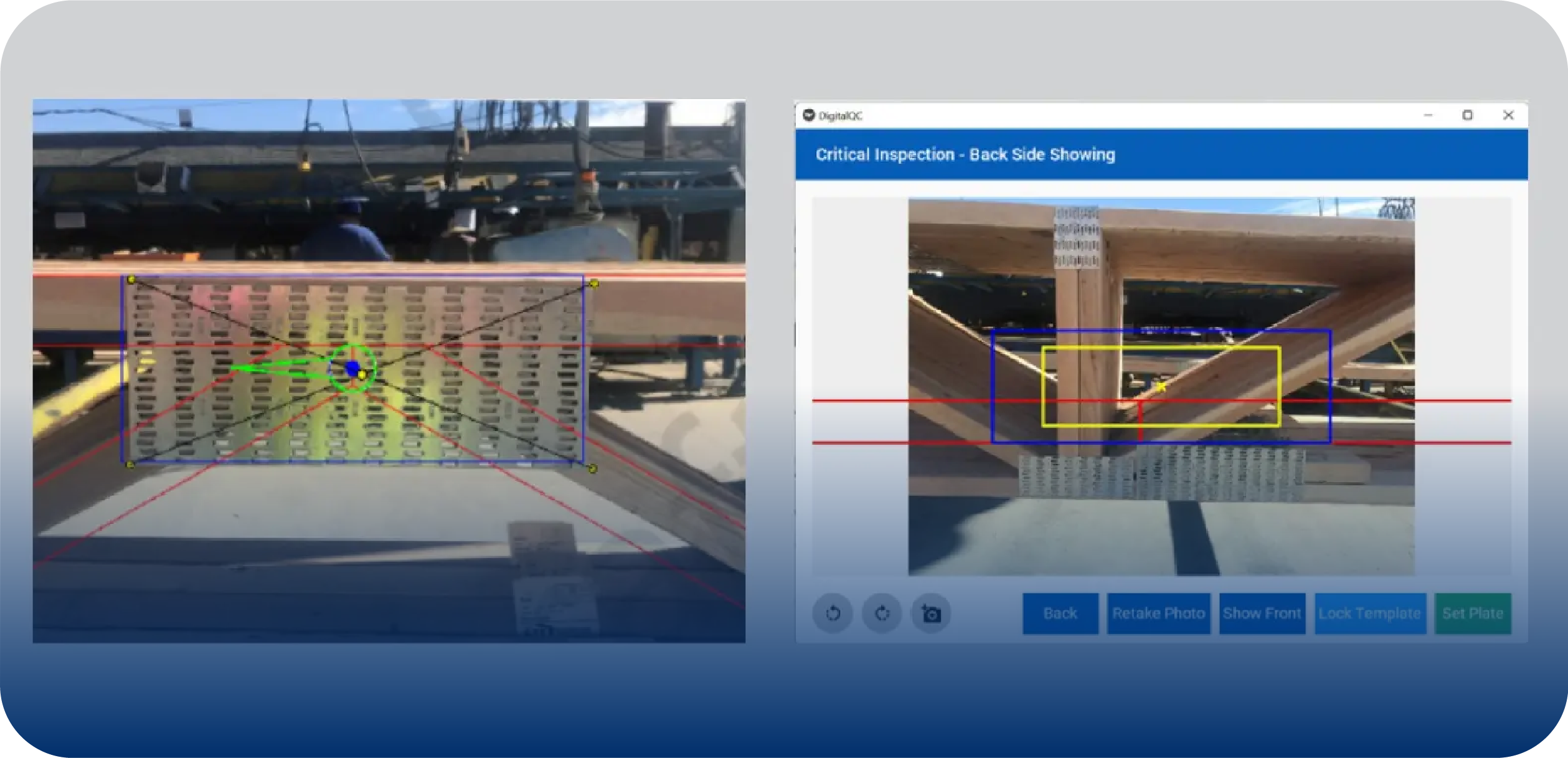

SBCA Digital QC

One of Q4US's significant accomplishments is the development of the Digital QC Application and Server for the Structural Building Components Association (SBCA), which is widely used by truss manufacturing companies in the US. This serves as a recognition of the company's domain expertise.

Job Management Tool

The application streamlines job management for multiple plants, featuring date setups (request, fabrication, delivery), designer assignments, plant allocations, status updates (design, production, delivery), sales rep tracking, resource allocation via build hours, email communications, and document management.

Truss Design Validator and Manager

This application visualizes truss design data and allows users to adjust and approve trusses to be built in automated truss production lines. It provides multiple ways to load designs and manage truss data files and jobs.

Production Lineup Manager

This serves as the central hub for order sequence management, facilitating user interactions for production lineup creation, modification, and scheduling, while also ensuring effective communication with production software and saw control. Its user-friendly frontend provides streamlined control over the production lineup management process.

Saw Control Application

The Saw Control application plays a crucial role in the execution phase by dynamically generating saw file templates based on lineup messages from the Production Lineup Manager, ensuring accuracy, offering a user-friendly interface for real-time buffer capacity information retrieval, and enabling informed decision-making for efficient task execution in the cutting process.

Mobile App to Follow-up Orders

The multi-platform (iOS, Android, and Windows) mobile app allows employees to seamlessly follow up on order-related information and access, search, and manage order documents directly from their smartphones, making it especially beneficial for salespeople on the go.

Common Hub

Common hub is a central user interface that has facility to manage multiple application related to a truss manufacturing operation. Rather than opening multiple applications, Common Hub allows users to seamlessly move between the applications.

Jig to Jig Optimization

Here, the system analyzes the jobs and ensures that, rather than completely removing the jig setup and redoing it, it keeps the tools that are common for the next job as is. This allows to optimize the truss-building process and save time.

Truss production control user interface

This is the primary user control interface for an automated truss production plant. It will provide a unified view of the state of production and communication with other tools.

I've always been impressed by Q4US's software expertise and their consistent dedication...

I’ve known the Q4US team and the excellent work they do for a long time. Their software expertise, work ethic and approach to projects has always impressed me. It’s rare to find a team like Q4US as they are well-versed in not only our industry but understand the language we use. They are well-equipped to provide software solutions for both the manufacturing and business processes. I highly recommend their services to all our partners

Ben Hershey

CEO, 4Ward Solutions Group

A trusted partner for a tailor-made digital transformation journey...

We have long recognized the need to digitally transform our business. This is where Q4US emerged as an incredible partner. What sets the Q4US apart is their approach towards understanding our unique needs, leading to tailored solutions that effectively address our issues. The team’s exceptional domain knowledge and extensive experience in the truss industry make them uniquely equipped to propose optimal solutions. For anyone in the truss manufacturing sector seeking a reliable technology partner, I wholeheartedly recommend Q4US

Stacey Timmons

Executive Vice President – Technical Operations, Atlantic Building Components – Truss Manufacturing, Atlantic Construction Services – Turn-key Framing

The perfect blend of industry knowledge and software professionalism...

Q4US has been an amazing partner for SBCA. They were very approachable with our initial ask and ‘bought in’ to our needs during the pre-study process which set us up for success. The Q4Us team maintains communication throughout each product sprint and has managed to regularly deliver software on budget and on time! Beyond their software development professionalism their knowledge of the truss industry makes them a perfect fit for our needs. I definitely recommend them to anyone with challenging software development needs!

Jess Lohse

Executive Director, Structural Building Components Association (SBCA)

It’s a 100% YES.

We wouldn't be here without them...

Q4US crucial for timely market deployment despite complexity. Deliverables punctual, well-documented. Communication transparent, efficient. Collaboration? YES.

Teemu Konttinen

COO/ Co-Founder, EAS Project Oy

Our long-standing partner in overseeing software processes from start to finish...

Q4US, our longstanding software partner for automated truss manufacturing, enhances quality and streamlines processes. Highly recommend them for any organization.

Jari Ketoluoto

CEO, Trussmatic Oy

I've always been impressed by Q4US's software expertise and their consistent dedication...

I’ve long admired Q4US for their exceptional work and expertise. Their understanding of our industry’s language and ability to address manufacturing and business needs make them invaluable. Highly recommend their services to all partners.

Ben Hershey

CEO, 4Ward Solutions Group

Their outstanding work helped us gain control of our data...

Q4US empowered our data management, ensuring complete control over customer data. Highly recommend their excellent work for any potential client; seeking long-term collaboration due to their diligent, efficient, and high-quality service.

Kristoffer Laurson

CEO, PAS Solar

A trusted partner for a tailor-made digital transformation journey...

Q4US, our invaluable digital transformation partner, excels in understanding our unique needs, offering tailored solutions with exceptional industry knowledge. Highly recommend for any truss manufacturer seeking reliable technology support.

Stacey Timmons

Executive Vice President – Technical Operations, Atlantic Building Components – Truss Manufacturing, Atlantic Construction Services – Turn-key Framing

The perfect blend of industry knowledge and software professionalism...

Q4US, an exceptional partner for SBCA, excels in understanding and delivering timely, cost-effective software solutions tailored to the truss industry. Highly recommend their services.

Jess Lohse

Executive Director, Structural Building Components Association (SBCA)

Explore More

Innovation

Innovation Q4US at BCMC ’25

We are grateful for all the insightful conversations we had with attendees at BCMC ‘25. These ideas and observations will...

Innovation

Innovation DIGITAL QC: Revolutionizing Quality Control for Roof and Floor Trusses.

“I think it is a really powerful tool to the components manufacturers. The data that we are going to collect...

Innovation

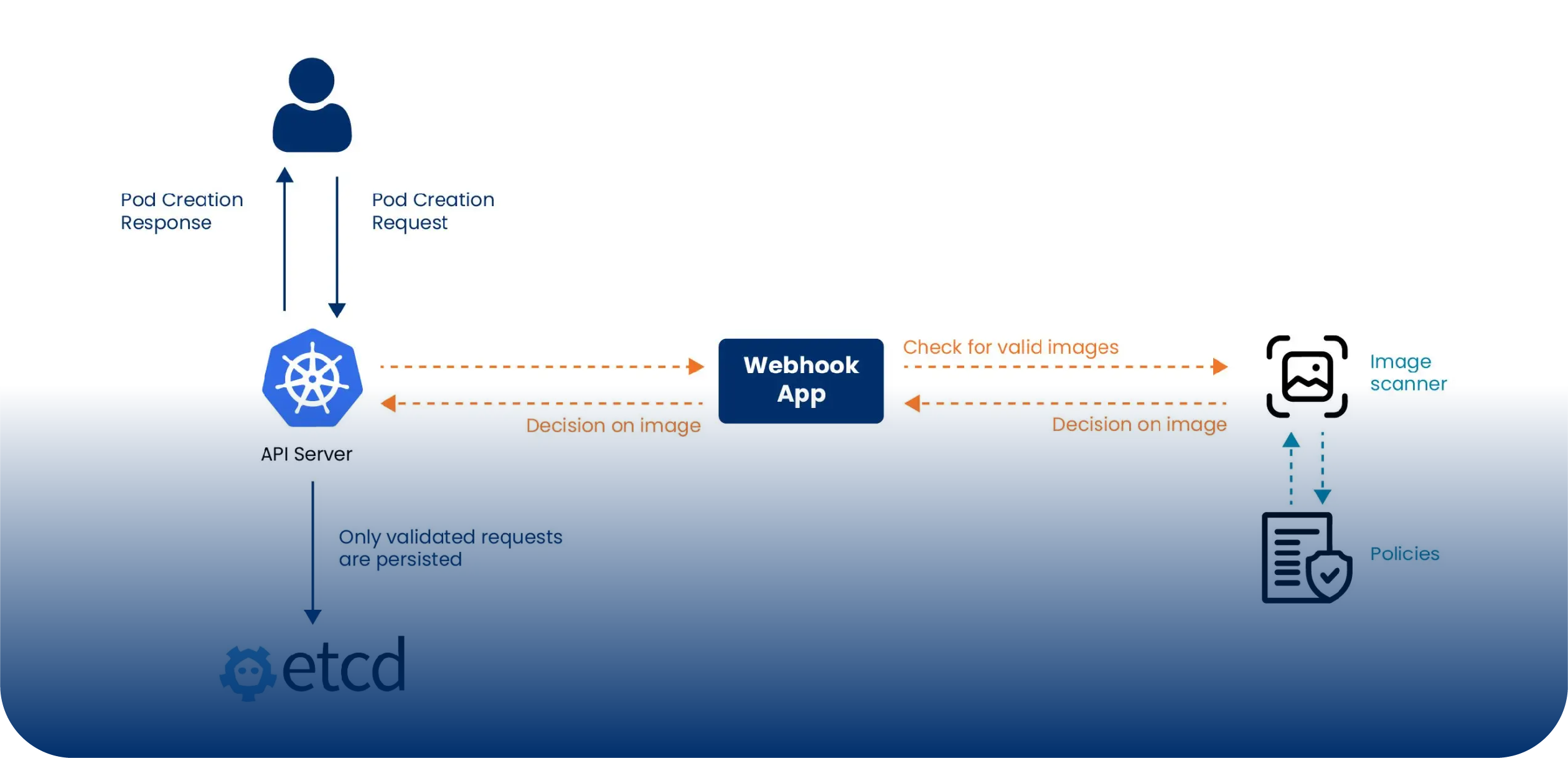

Innovation Kubernetes Security Hardening – Image Whitelisting

BackgroundWe are using Docker containers in Kubernetes environments to host all our workloads. This required us to start looking into...

Innovation

Innovation FAQ on Unit Testing

Software quality is an essential feature of sustainable software. Clients require software that not only meets their requirements but is also...